Calibrated Short Link Chain

Internationally, this is accepted as chain with a link of outside dimensions not exceeding 5 times the material diameter in length and 3.5 times in width – e.g. 10mm chain cannot have links larger than 50mm x 35mm outside dimensions. Excluding stud link chain, short link chain, size for size, is the strongest, heaviest and most flexible of chains, and as such is the best choice for mooring and anchoring. Unfortunately, the links are too short to accept shackles of reasonable size, necessitating the fitting of large end links. In effect, short link chain needs to be assembled into a ‘bespoke’ mooring assembly.

Click here for PDF of Short Link Chain

Medium Link Chain

These chains have a link of outside dimensions not exceeding approximately 6 times the material diameter in length and 3.6 times in width – e.g. 10mm chain, generally would not have links larger than 60mm x 36mm outside dimensions. Mid link chains are a good compromise, as they offer most of the benefits of short link with the advantage that they will accept like sized shackles without the need for special end links.

Click here for PDF of Medium Link Chain

Long Link Chain

These chains have a link of outside dimensions not exceeding approximately 8 times the material diameter in length and 4 times in width – e.g. 10mm chain, generally would not have links larger than 80mm x 40mm outside dimensions. Long link chains are also a popular choice for mooring applications, as they offer greater internal dimensions to facilitate a wider range of associated fittings without the need for special end links. They also offer a lighter weight to ultimate breaking strength ratio, which can often be an issue when choosing the correct mooring buoy.

Click here for PDF of Long Link Chair

Swivels

There are various designs of swivel available and the user should ensure that the one chosen will accept the correct size shackle or shackle pin.

Click here for the PDF of Swivels

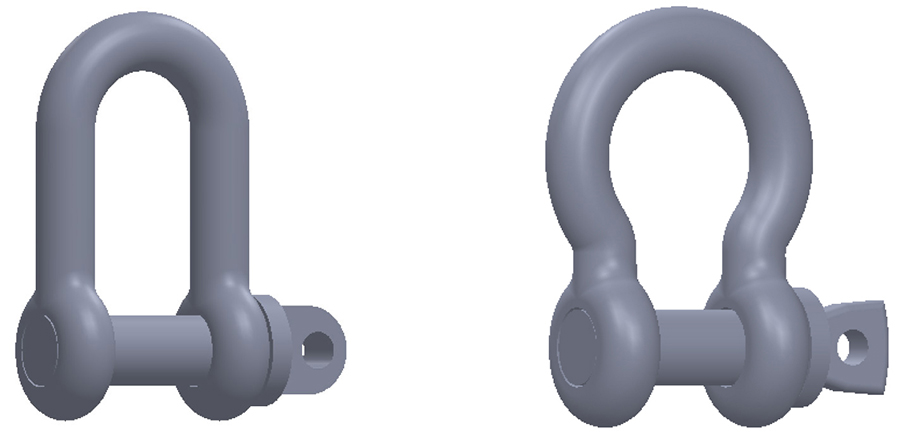

Shackles

By far the most popular shackle types are dee and bow shackles to BS 3032, screw pin, although similar shackles to US Federal Specification are also commonly used as a means of connection. Care needs to be taken when choosing shackles to these standards as there are many poor-quality imitations currently in the market place. These can range from incorrect material used, lack of correct heat treatment and poor manufacturing / machining processes leading to inferior quality products and ultimately potential failure in service.

Click here for the PDF of Shackles

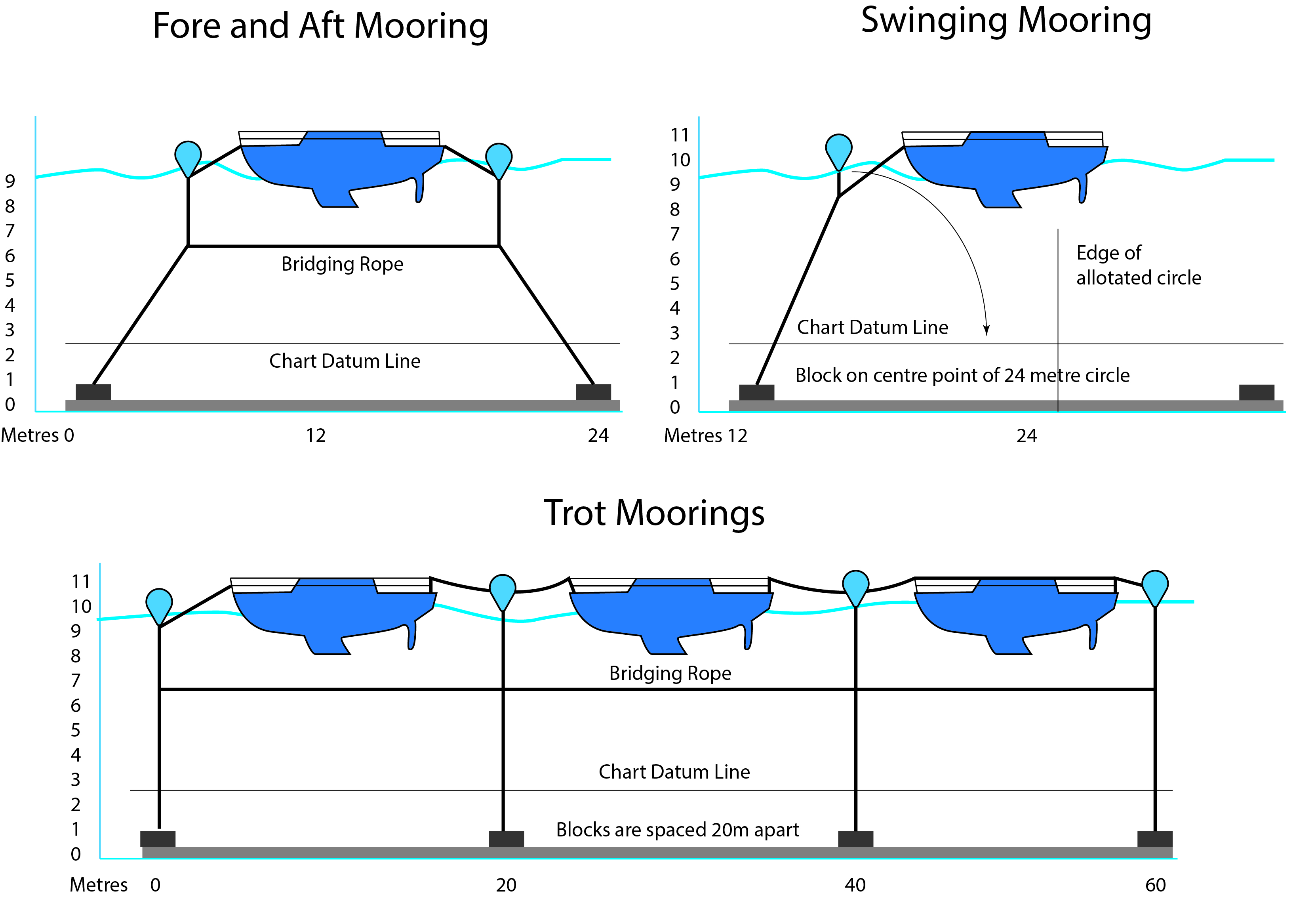

Laying A Mooring

When any type of permanent mooring is assembled, there are a few basic rules to bear in mind. Unless the mooring is a complete all-welded assembly, shackles or some other form of mechanical connectors will have to be used. These are almost invariably weaker, size for siz e, than the chain and although in a well-designed system, loads should be modest, it makes good sense if all components are of roughly comparable strength. Therefore shackles (and swivels) should be chosen which are at least one size larger than the chain. Rings, often used between bridle and pendant, need to be substantially larger to achieve equivalent strengths. Shackle pins are another problem area. Screw pin shackles are by far the most popular, but the threads can corrode more rapidly, and the pins work loose. There is no easy solution, but at the least, all shackle pins should be very securely moused (wired). A thick solid wire should be used for mousing and never wire rope, where deterioration is rapid and possibly hidden from view.

Before finalising your choice of mooring position with your local authority or club, consult your local mooring contractor as to whether the area is safe for your vessel and that the mooring chain, shackles and swivels are adequate in relation to the size of your vessel, the prevailing conditions and that there is sufficient depth of water.

Click here to view a PDF of this image

Click here to view a PDF of this image